Engineering Excellence

Our Services

Design Development/Simulation

SIVMECH COMPONENTS INC is capable of developing New product from scratch. From material to use to final design, SIVMECH COMPONENTS INC is always ready for new challenges. We have state of art technology, CAD/CAM and structural as well as thermal simulation software for developing and testing the new design. SIVMECH COMPONENTS INC follows V-model for developing a new product.

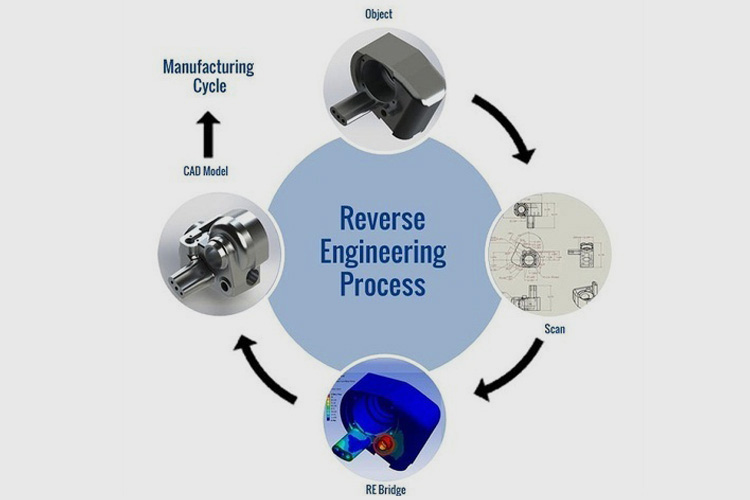

Reverse Engineering

SIVMECH COMPONENTS INC has capability of developing or improving new designs or prototypes through the process of reverse engineering. The 3D scan of the product is carried out at the initial stage and on the basis of this scan, a design is developed and from this design, many improvements are carried out on the basis of simulation-based testing. An improved designed is then generated for the final prototype development, which is further carried forward to the manufacturing department after all approvals.

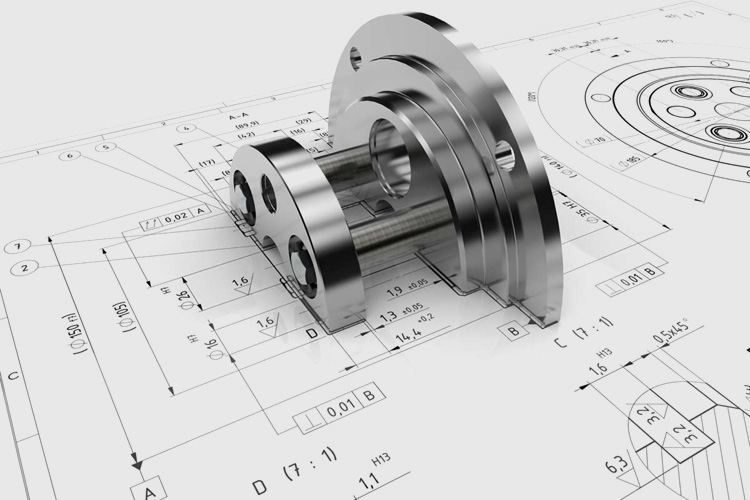

Prototype Development

SIVMECH COMPONENTS INC is capable of developing prototype at ease. The prototypes are developed as per the requirements of the customer. With the capability of state of art CNC machines, and CAM software the process of prototyping is very rapid in the campus of SIVMECH COMPONENTS INC. With the wide range of gauges available at site and fully equipped Measuring and Quality Lab, SIVMECH COMPONENTS INC has the capability of developing 100% accurate prototypes in Short period of time.

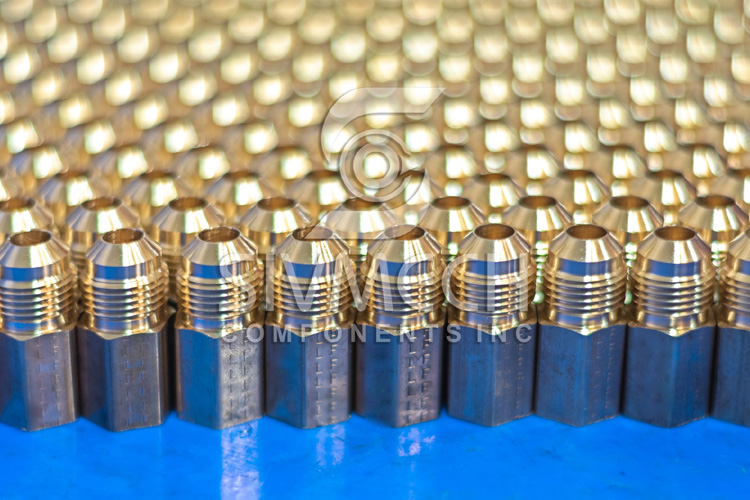

Production

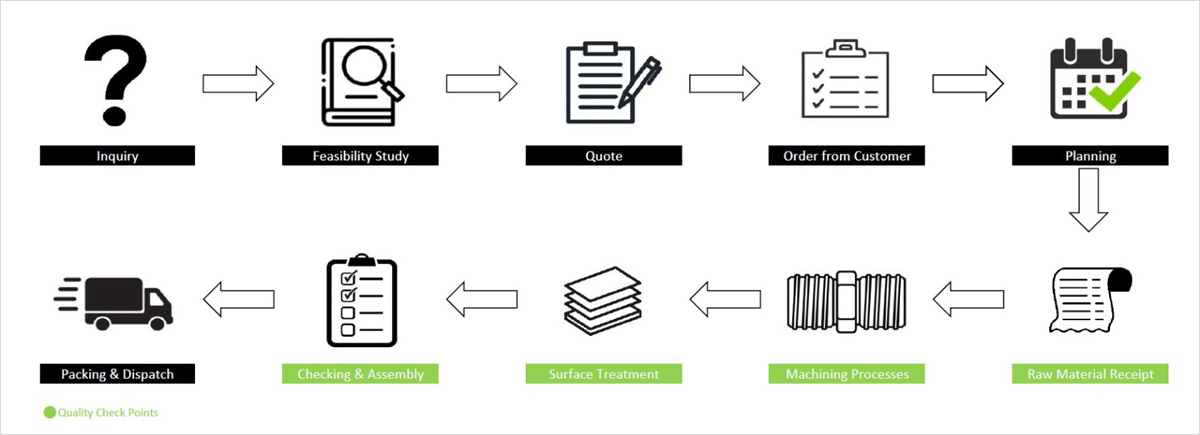

For consistent quality during mass production, we follow control plans & procedures:

We have implemented Production Part Approval Process (PPAP) to understand all customer engineering design specifications and requirements by which we improve communication with our customer. The PPAP process also confirms that the processes used to manufacture parts can consistently reproduce the parts at defined quality levels and in compliance with specifications. We can submit PPAP level 1 to 5 documents as per customers’ requirement.